Boiler Makeup Water System

Based on the three core technologies of curve micro power membrane separation technology, U-CDI desalting device and Muncotte-Ion multi-frequency deionization system, combined with the actual situation of local water quality, we provide the customization machines with stable performance, easy operation, safe and energy conservation features, as well as efficient, water-saving, small footprint, low operating costs, professional boiler water treatment solutions.

Cases:

Boiler desalinated water project 3 * 60m3 / h in Panjin Shengyuan Thermal Power Co., Ltd.

Unique advantage

● Unique membrane technology, more stable, energy-efficient;

● HIRO system design, water utilization rate reaches up to 98%;

● High desalination rate, stable water quality, long service life, high efficiency, low noise;

● Highly automated design, truly unattended, APP remote control;

● On-line monitor, can monitor the product water flow, water quality and system recovery situation at any time;

● POD online inspection system and circulating cleaning system ensure no unqualified product water, so as to ensure long-term stable operation;

● Over 2000 large-scale boiler make-up water projects experience, covering hot water boilers, medium and high pressure boilers, high temperature and high pressure boilers and other water systems.

Applications

Power plants, heating companies, enterprise-owned boilers.

Boiler Makeup Water System

Based on the three core technologies of curve micro power membrane separation technology, U-CDI desalting device and Muncotte-Ion multi-frequency deionization system, combined with the actual situation of local water quality

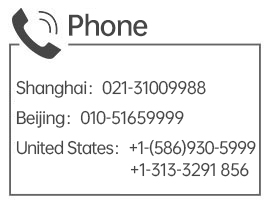

Home

Home About us

About us Cases

Cases Contact us

Contact us