“Zero Discharge” System

The “zero discharge” system based on a number of patented technologies and innovations, according to needs of different customers, integrate the advantages of technology and the overall management of industrial water cycle to enhance the industrial “zero discharge” efficiency of the liquid to achieve optimum reuse and the ultimate “zero” discharge, and provide wastewater “zero discharge” solutions for industrial customers around the world.

Rich experience

● Domestic first-class, internationally renowned wastewater “zero discharge” institute, 14 years of continuous breakthroughs in technical problems;

● Unique ZERO efficient water treatment process;

● Integrated system;

● Application of “cloud” technical support services, automatic remote control;

● Applicable for electricity, medicine, electronics, petrochemicals, automotive, printing and dyeing, food, coal, municipal and more than 20 industries.

Unique process

The ZERO process is RIGHTLEDER’s proprietary efficient water treatment process, including chemical softening, special high-density clarification tank, media filtration, shell resin softening, micron filtration and high efficiency curve micro power membrane separation technology and other water treatment technology, fully embodies RIGHTLEDER’s ability in wastewater “zero discharge”, salt recycling “full solution” system integration.

Process advantages

● Put membrane technology as the main body to achieve “zero liquid discharge” and salt recycling, water production standards to achieve reuse, reduce operating costs;

● RLT-60 series of unique shell resin softening process, the regeneration can be concentrated brine;

● to achieve the recovery of salt and organic matter recovery, biochemical treatment to reduce the amount of water and the difficulty of biochemical treatment;

● reuse of spent caustic soda to reduce the production process of the addition of new alkali and wastewater discharge;

● The acid is purified and reused. The organic matter or the metal ion in the acid liquid is separated, and the treatment difficulty of the low acid wastewater is reduced;

● Stable operation, safe and reliable, low drug consumption.

Professional technique

In recent years, RIGHTLEDER achieved remarkable results in the research and development and innovation of membrane concentration, separation and MVR-H evaporation and crystallization technology. Its MVR-H evaporation technology provides an effective way to reuse and recycle the wastewater, and the recovery rate is up to 98%; On the upstream and downstream of the evaporation crystallization equipment, it adopts micron-scale filtration, shell resin softening, curved micro power membrane separation system, dewatering system, clarification technology and a series of professional processing technology, thus forming an integrated “zero discharge” system.

Applications

Electricity, steel, mining, coal, petroleum, chemical, textile, printing and dyeing, automotive, electronics, paper making, printing, food, machinery, electroplating, municipal, pharmaceutical, surface treatment, biofuels, waste treatment.

“Zero Discharge” System

The “zero discharge” system based on a number of patented technologies and innovations, according to needs of different customers, integrate the advantages of technology and the overall management of industrial water cycle to enhance the industrial “zero

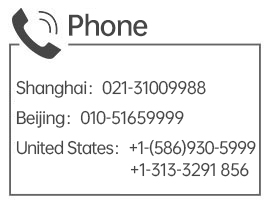

Home

Home About us

About us Cases

Cases Contact us

Contact us